How to build a generator using an electric motor

Ever wonder how to make your own generator using an electric motor? There are many different types of generators that can be created using an electric motor. Building a generator allows you to tap into free electricity from the sun, water, wind or other sources.

Have you ever done a project and wished you had a generator to power all your tools? Generators are very noisy and use a lot of energy. Buying one can be expensive and there’s no way to make your own. This is where an electric motor really shines. It can turn electrical energy into mechanical energy using electromagnetic induction,12v dc motor generator output how to build a 220v generator allowing for much more efficiency. In this tutorial I’ll walk you through the process of building your own generator using an electric motor.

How to build a generator using an electric motor

The easiest way to make a generator is to use an electric motor, like the one in your car or truck. You can find electric motors at any auto parts store, but you may have to ask for them by name. They are sometimes called “generators” or “generator sets”.

A simple 12v dc motor generator output will produce around 5 volts and 1 amp at full load. This is enough power to charge your cell phone, but not enough to run most modern electronics (iPod, laptop computer).

If you want more power, you need a larger motor with higher voltage and current outputs. For example: A 12v dc motor generator output produces around 5 volts and 1 amp at full load. If the output is increased by using a 24v dc motor instead of a 12v dc motor, then the output voltage would increase by 2x (24 = 2 x 12) which means that we now have 24 volts and 2 amps of output power available!

A generator is a device that converts mechanical energy into electrical energy. The reverse process, that of converting electrical energy into mechanical energy, is called an electric motor. The motor and generator have many similarities, and the fundamental operating principles of both devices are based on the same electromagnetic principles discovered by Michael Faraday in 1831. This article will describe how to build a dc motor generator using an electric motor and some basic electronic components.

The first step in building a dc motor generator is to choose a suitable electric motor. Most motors found in consumer appliances (such as vacuum cleaners) are designed for 12 V dc operation, but you can also find other types of motors such as those used in portable drills and power tools. Any type of dc motor will do, but if you intend to use your new generator to power sensitive electronics (such as computers), then you should use one rated at a voltage higher than 12 V dc because this will reduce the risk of damage due to overvoltage spikes caused by inductive loads (such as motors).

One way to reduce the risk of damage due to overvoltage spikes is to use an electronic regulator circuit connected between your battery pack and your load(s). These circuits typically contain an adjustable current threshold level (typically around 5 A), after

Generators are an important part of any home-based operation and can be used to power everything from a small workshop, to a machine shop or even a full-scale factory.

Generators are designed to convert mechanical energy into electrical energy. The most common type of generator is the synchronous motor generator, which uses the principle of magnetism to produce electricity. These generators use either AC (alternating current) or DC (direct current) power.

Synchronous motor generators are very easy to build, requiring only basic tools and materials. This guide will show you how to build your own generator from scratch, using simple parts that you can find at any hardware store.

The generator is a device to convert mechanical energy into electrical energy. The main purpose of this conversion is to supply electricity to remote locations, such as in the field or in an isolated community.

The first step in building a generator is choosing the right motor for your project. We recommend using a 12V DC motor with about 2-4 horsepower and at least 1000 RPMs.

You’ll also need some additional tools:

A soldering iron or glue gun (to attach the wire)

A drill with a 1/8″ bit (to make holes in both ends of the pipe)

Wire stripper / cutter (to strip off insulation on wires)

Wire crimper / cutter (to crimp connectors onto wires)

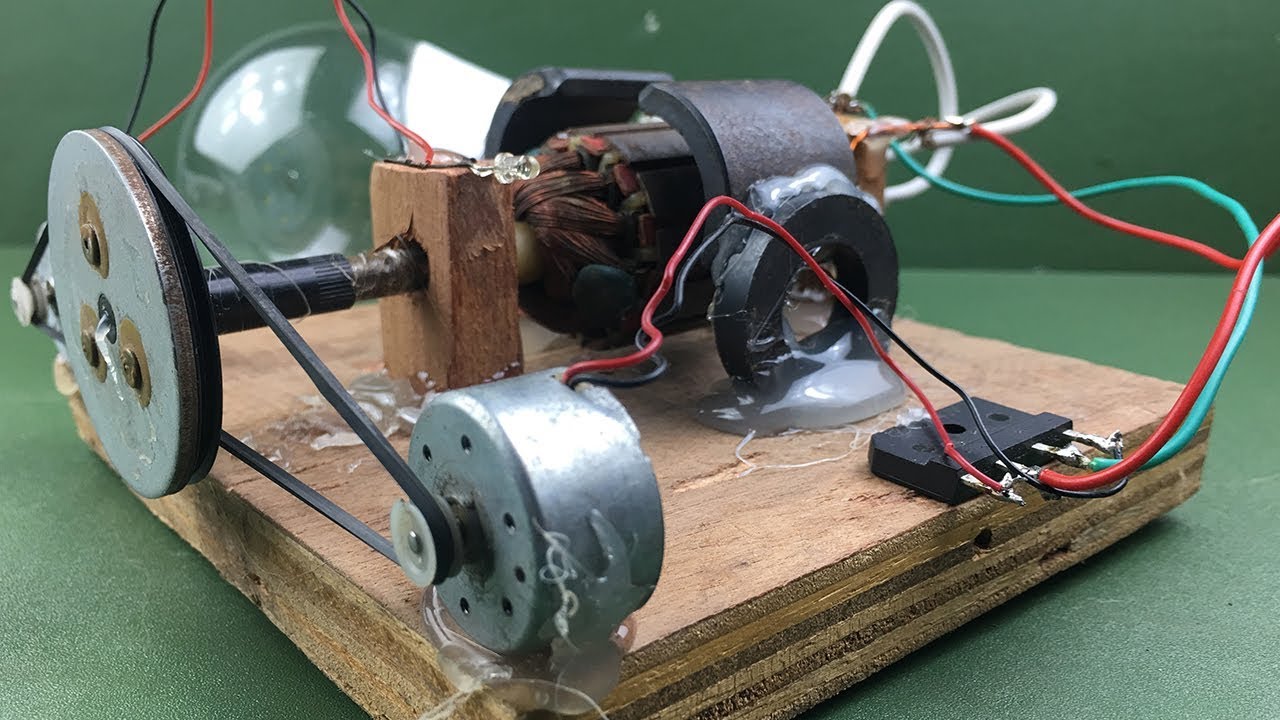

Generator construction

The generator consists of a 12v DC motor, a pulley and a belt. The diagram below shows the basic components and how they are connected.

The 12v DC motor is connected to the shaft of the pulley using a small metal piece called an axle. The motor’s power leads are then connected to the terminals on the side of the pulley. The pulley has grooves cut into it for holding the belt in place with no need for any fasteners or glue.

The pulley is attached to the shaft of your motor using an axle (sometimes referred to as a spindle). You can buy axles at any hardware store that carry motors like this one:

There are two different types of axles available: steel and brass. Steel axles tend to be stronger but can be more difficult to cut and drill because they are harder than brass ones. Brass axles are easier to work with because they are softer than steel but may break if you hit them too hard or bend them too much (which would cause them to snap). I recommend using steel axles over brass ones unless you have access to an electric drill press or other device that makes drilling holes easy without damaging small parts